Biological Safety Cabinets

A Biological Safety Cabinet (BSC) is a primary engineering control used in a biological laboratory designed to safeguard laboratory personnel, the work conducted within, and the surrounding environment. BSCs use laminar airflow and high-efficiency particulate air (HEPA) filtration to contain aerosols, preventing airborne contaminants from escaping the cabinet. The HEPA filter removes particles ≥0.3 µm (essentially including all bacteria, spores, and viruses) with an efficiency of 99.99%.

BSCs are designed to:

- Protect the operator from biohazardous agents used inside the cabinet

- Protect the sample from contamination

- Protect the laboratory environment from contaminants within the cabinet

Use BSCs when performing activities that could generate droplets, splashes, or aerosols with biohazardous or potentially infectious materials (e.g., BSL2, BSL3 organisms). Operations such as centrifugation, vortexing, sonication, and opening containers of infectious materials whose internal pressure may differ from the ambient pressure are known aerosol-generating procedures.

Note: Chemical fume and laminar flow hoods are not BSCs. They both fail to provide the same protections as a BSC. For additional information on the different laboratory hoods, refer to this document.

Standard Operating Procedures

For details on operating, certifications, and ultraviolet (UV) light use, refer to this SOP for the Safe Operation of BSCs.

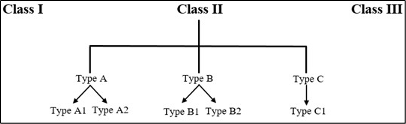

Classes and Types of BSCs

The National Sanitation Foundation (NSF) sets BSC classifications and standards for the United States. Three BSC classifications, Class I, II, and III, have been developed to meet varying research and clinical needs. NSF defines four types of Class II cabinets (A1, A2, B1, and B2), distinguished by differences in airflow patterns and velocities, HEPA air filter positions, ventilation rates, and exhaust methods. The majority of BSCs at LSUHSC are Class II Type A2.

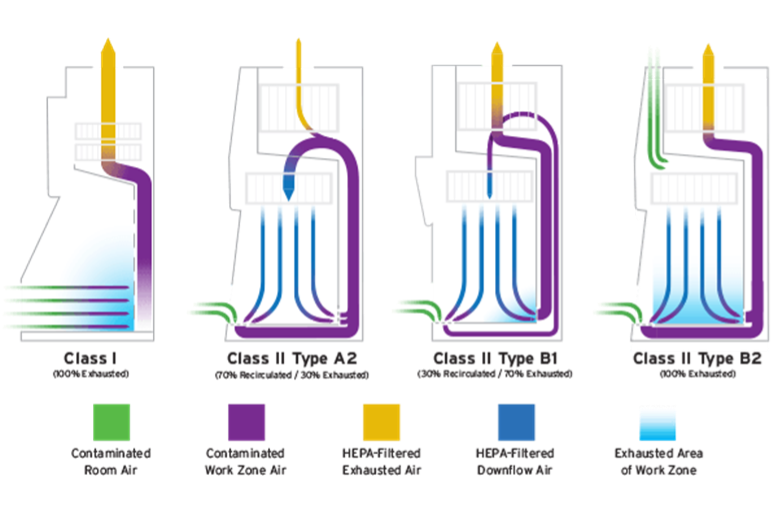

Class I BSCs

Class I cabinets provide personnel and environmental protection by filtering air through a HEPA filter before it is exhausted. These cabinets do not protect the product from contamination and are suitable for general manipulations of low-to-moderate risk agents where product sterility is not a priority.

Class II BSCs

Class II cabinets protect the product, personnel, and environment, making them ideal for handling microbiological and biotechnological materials that require aseptic conditions.

- Type A1: Used in clinical and research laboratories for standard microbiological work without

chemical evaporation. They maintian a minimum inflow velocity and recirculates 70%

of the air while exhausting 30% outdoors after filtration. These cabinets are not

suitable for handling volatile or toxic chemicals.

- Type A2: These are like Type A1 but with increased inflow velocity, enhancing containment.

They can handle minute amounts of volatile chemicals if vented with a thimble (canopy)

connection to the facility’s HVAC system. A2 cabinets recirculate 70% of air through

the cabinet, and 30% is exhausted back into the laboratory through HEPA filters.

- Type B1: These cabinets support work involving minute quantities of toxic chemicals and radionuclides.

They recirculate 30% of air, and 70% is exhausted outdoors through HEPA filters.

- Type B2: These cabinets are suitable for handling significant quantities of toxic chemicals and radionuclides. All inflow and downflow air is ducted out of the building, exhausting 100% of the air outdoors and providing no recirculation within the cabinet.

Class III BSCs

Class III cabinets are gas-tight enclosures that offer the highest level of personnel and environmental protection for use with high-risk microbiological agents and hazardous chemicals. Users place their hands into mounted gloves that pass through a non-open window to manipulate all work (e.g., a glove box).

Training

Training in the use of BSCs is the responsibility of the Principal Investigator. Training may be accomplished in various methods and must be documented by the laboratory.

If additional training or resources are needed, contact the Biological Safety Officer at safety@lsuhsc.edu or 504-568-2324.

Certifications / Repairs / Decontaminations

EH&S coordinates mandatory annual certifications and, as needed, repairs and decontamination of BSCs with the LSUHSC contracted vendor. Work in a BSC is only allowed with a current certification. Certification is required when:

- A BSC is initially installed and at least annually.

- A BSC undergoes significant repair/maintenance.

- A BSC is moved.

Decontamination is performed by a certified technician and is required when:

- A repair involves an internal part, such as a HEPA filter replacement.

- The BSC will be moved.

- The BSC will be decommissioned and disposed of.

If your BSC is not working correctly or alarming, submit an online work order request to EH&S here.

Purchases / Replacements / Relocations / Disposals

EH&S is solely responsible for the procurement of BSCs. Individual purchase of a BSC is not allowed. Complete the online Biological Safety Cabinet Purchase Request Form to request a new or replacement cabinet.

Never attempt to move a BSC yourself. Notify EH&S of all BSC relocations, even within the same laboratory space.

For additional instructions on acquiring, moving, or disposing of a BSC, refer to Purchase/Replacement Guidance document.

Vacuum Aspiration System Protection

Vacuum systems are frequently used to aspirate liquid waste inside a BSC. A vacuum flask system is required to protect the central building vacuum system or vacuum pump and personnel who service the equipment. For guidance on assembly, use, and maintenance, refer to EHS-300.07 Biological Material Vacuum Aspiration Procedures.

To extend the life of your BSC and ensure a safe working environment, follow these tips:

- Minimize the storage of materials in and around the BSC.

- Avoid storing items on the cabinet since it can damage the HEPA filters.

- Do not use Bunsen burners in the cabinet - This disrupts the airflow and damages the HEPA filters.

- Do not use volatile or flammable chemicals inside the cabinet – They will recirculate back into the room and create a fire hazard.

- Never operate the blower with the sash closed. Excessive air inflow could rip the HEPA filters and damage the sash.

- If a UV light is present, use it only as a supplemental disinfection method, as needed. Never have the UV on when someone is in the room.

- Clean any spill immediately to prevent staining of the surfaces.

- Disinfect the inside of the cabinet after every use with a 10% bleach solution followed by 70% ethanol. This prevents corrosion and damage to the BSC’s internal parts.

- Turn the BSC off after use – Do not leave it running overnight.